DACOS® | Digital Antonello Croce Occlusal System

DESCRIPTION

DACOS by Antonello Croce: Repositioning Final Digital Dentures with Precision

CATEGORY

3D Printing

CONTRIBUTOR

Antonello Croce

DATE

01/08/2025

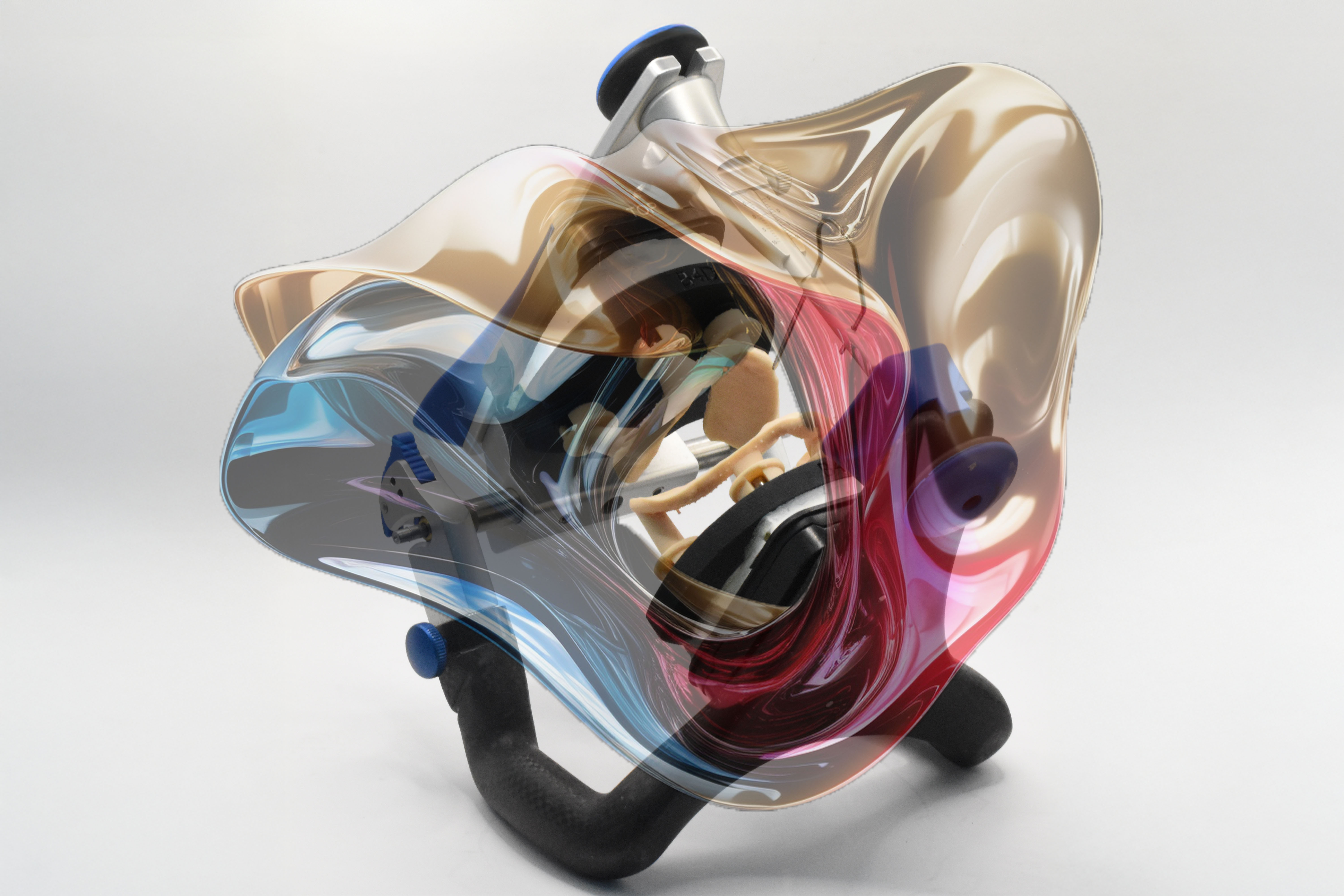

In the evolution of digital prosthodontics, one challenge has persisted: how to reposition a final denture produced via 3D printing or milling—back into a traditional articulator without using master models. DACOS is the breakthrough.

Developed by Antonello Croce in collaboration with Ruthinium and Blender For Dental, DACOS (Digital Antonello Croce Occlusal System) is a next-generation solution that allows clinicians and technicians to remount final prostheses in the articulator using a dedicated, digitally designed device—directly from the STL of the final denture.

What Makes DACOS Different?

DACOS is not about models—it’s about the final restoration. Using a device integrated into the digital denture’s STL, the system enables highly accurate repositioning in the articulator, eliminating undercuts and avoiding manual remounting errors. Whether the denture is printed or milled, DACOS ensures it aligns perfectly with the occlusal plane without requiring traditional model creation.

The DACOS device is custom-designed during the CAD process, based on the final prosthetic’s geometry. This precision helps maintain the original digital coordinates of your design and improves efficiency across analog-digital workflows.

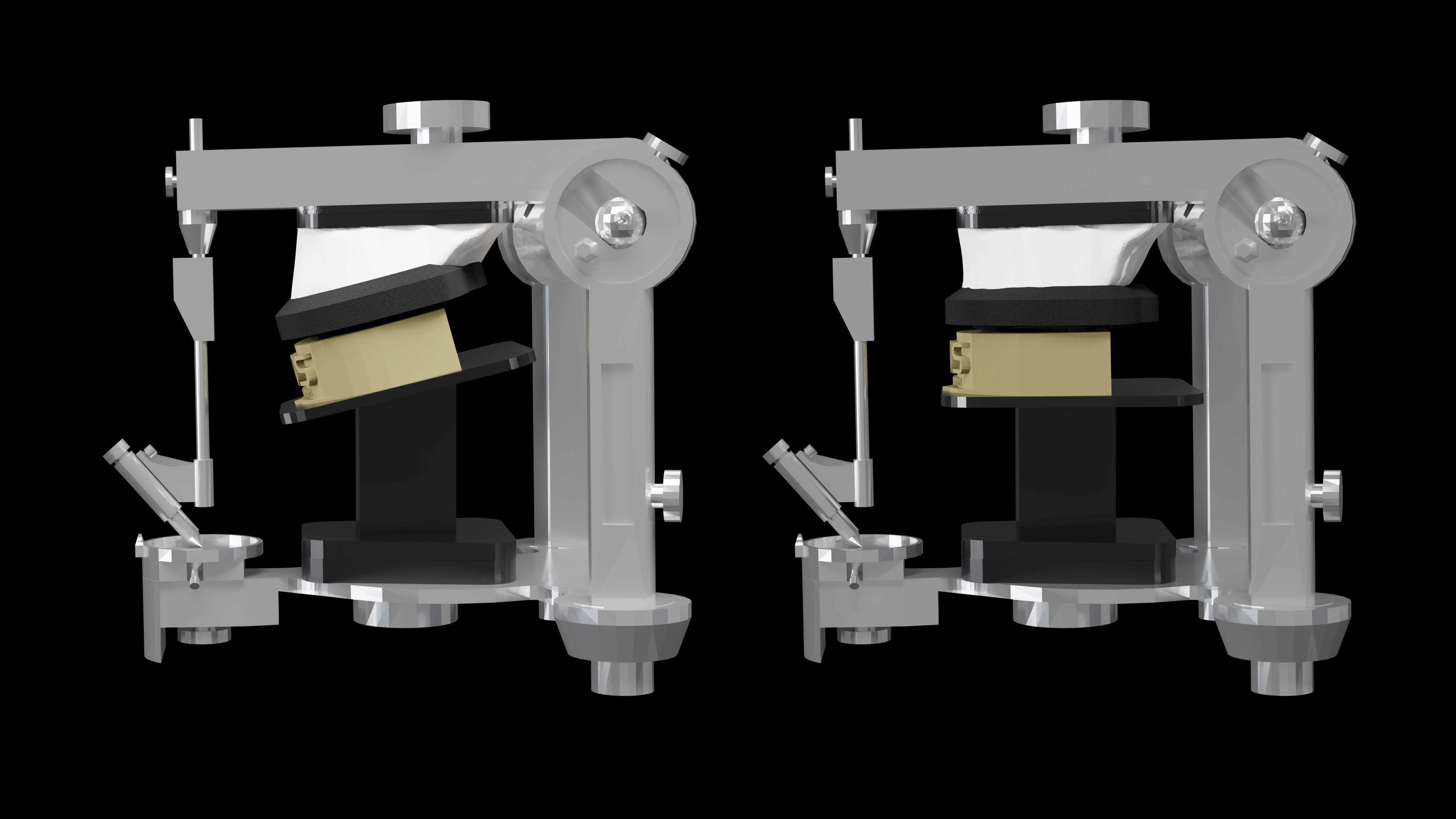

Software Component – Seamless Integration with CAD

DACOS is powered by a Blender For Dental module that can be integrated into existing workflows using leading CAD systems such as Exocad, 3Shape, and others. The module generates specific devices on the final denture STL file, tailored to your design.

These attachments are designed with minimal horizontal extensions and optimized support-free geometry. The internal architecture ensures zero interference in critical zones—no post-processing needed.

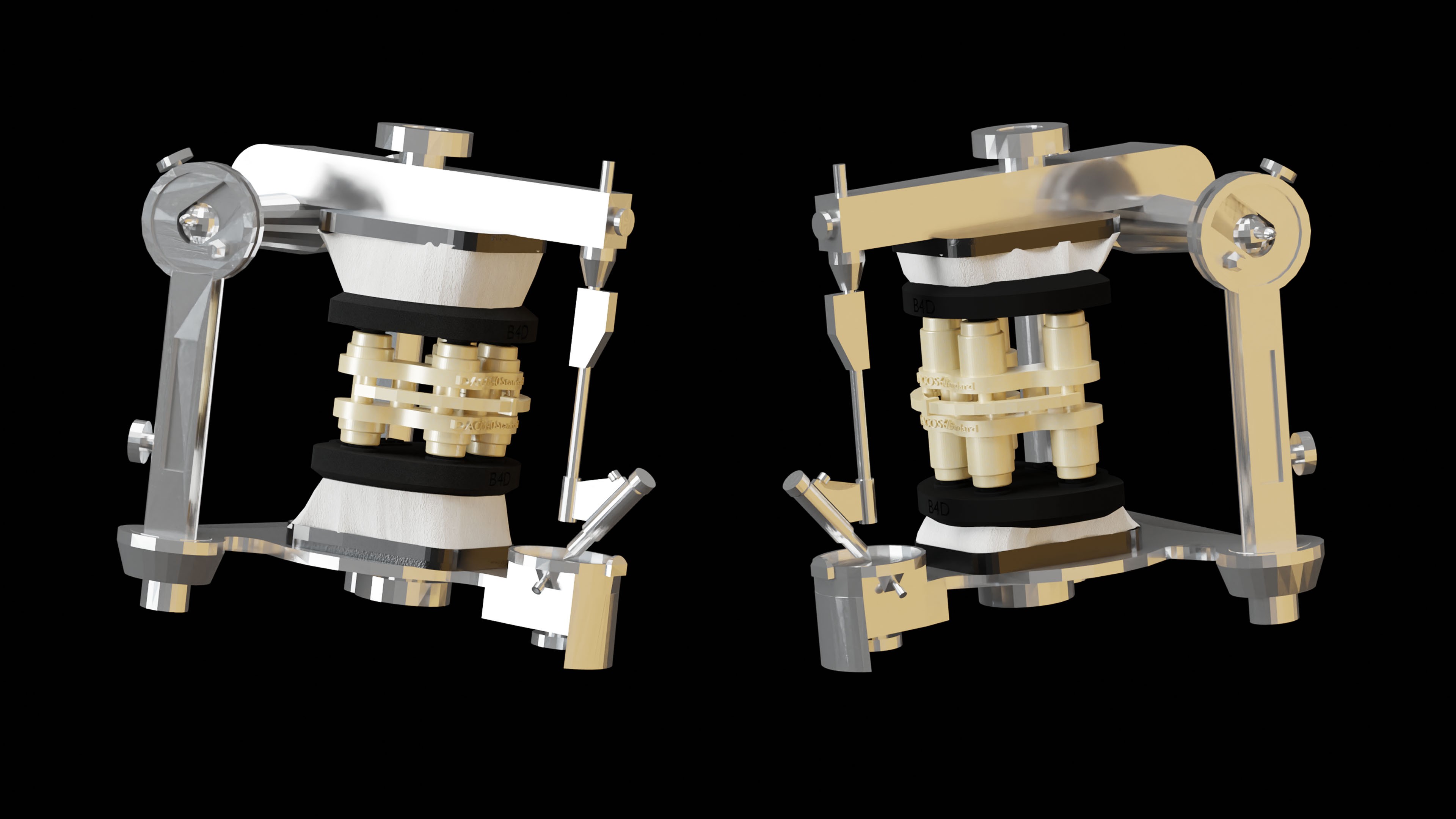

One-Time Articulator Setup – DACOS Plate

The system begins with installing a DACOS Plate into your articulator. Available in 40mm or 60mm variants, this plate is embedded once using plaster and remains fixed for future workflows.

To ensure precise spatial orientation, the DACOS Plate can be aligned using anatomical reference planes—CAMPER or FRANKFURT—thanks to the included PILOT CALIBRATOR tool. This ensures your digital dentures are mounted in a clinically relevant position every time.

CAMPER and FRANKFURT In Your Choice

DACOS pays meticulous attention to anatomical accuracy by including essential anatomical planes such as the CAMPER plane and the FRANKFURT plane. These planes are crucial reference points in dentistry that help align the dental models to the natural orientation of the patient’s head and jaw. By incorporating these planes into the system, DACOS ensures that every model you work with reflects real-world anatomical positions, enhancing the fit and function of the final prosthetics.

To facilitate this precise installation, DACOS provides the PILOT CALIBRATOR, a tool that guides you in setting up the DACOS Plate according to the desired anatomical occlusal plane. Whether you are working with the CAMPER or FRANKFURT plane, the PILOT CALIBRATOR gives you the flexibility to configure the system based on your specific clinical needs, ensuring optimal precision.

By downloading the Calibrator STL file, you can print the calibrator using the same 3D printer and resin you’ll use for your dental models. This personalized calibration eliminates variability across different printers and resins, ensuring a seamless workflow and guaranteeing that your system is fully optimized for your setup.

Join the revolution and take the next step in transforming your approach to digital dentistry.

Click the link to visit the company partners website to learn more about the DACOS system: 👉🏻 Blender For Dental 👉🏻 Ruthinium